|

ISNAD bridges are designed and constructed to British Standard 5400 Highway Bridge Loading Specification or other National Codes. Our Steel Bridges can be shipped and erected world-wide and are designed to suit a variety of applications and come in a variety of types dependent upon your specific bridge requirements, including:

|

|

Examples of Bridge Applications:

- Road Bridges

- Highway Bridges

- Pedestrian Bridges

- Railway Bridges

- Contractor's Bridges

|

|

Selection of Bridge Types:

- Composite Beam Bridge

- Through Truss Bridge

- Over Truss Bridge

- Cable-Stayed Bridge

|

|

|

|

|

|

Our services include the complete structural design and construction of your choice of bridge and we use only the highest quality steel, which can be supplied hot dip galvanized if required, we have included below some examples of steel bridge types and applications, below, we list the main types of steel bridges:

|

|

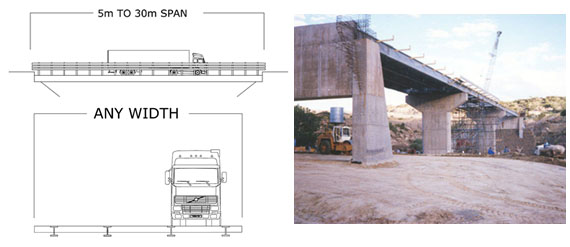

1. Composite Steel Beam Bridges

- Beam - Structurally, the simplest type of bridge

- Relatively short span - 5m to 30m, although become more expensive after about 15m

- Can be any width, and are easily widened by simply adding more beams and deck

- Frequently used in pedestrian bridges and for highway overpasses and flyovers

- Footpaths can be built on both sides

- Can be built one or two beams at a time, often by direct craneage or by cantilever launch

- Longer spans require supporting pillars, making them unsuitable if lots of space is required beneath

|

|

|

|

|

|

|

|

|

|

|

|

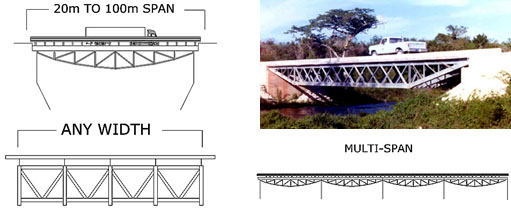

2. Over-Truss Steel Bridge

- 20m - 100m span

- Very similar to simple beam bridges, but the beams are replaced with trusses, making them much deeper and lighter

- Easily widened with additional trusses

- More complex to build

- Depth is typically 12% of the span, so the roadway has to be higher if the bridge is to have sufficient clearance over water, railways etc.

|

|

|

|

|

|

|

|

|

|

|

|

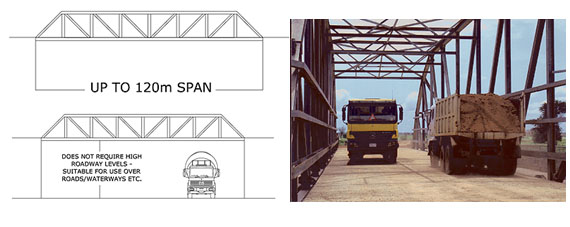

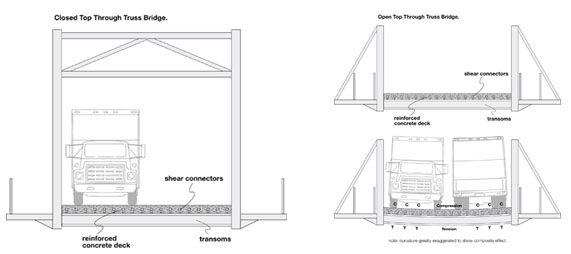

3. Through Truss Bridge

- Long span (50m - 150m)

- Very strong, but also flexible

- Economical as allow a slender and lighter structure which is still able to span large distances

- Light weight is an advantage in earthquake-prone areas

- Modern and simple design makes attractive and distinct landmarks

- Easy to build in segments where in-situ construction or cantilever launch on rollers is not possible. This requires substantial piers and large counterweights

- Less suitable for very windy places due to its lightness

|

|

|

|

|

|

|

|

|

|

|

|

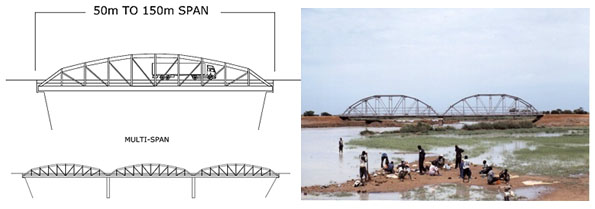

4. Steel Bowstring Girder Bridge

- Much like a through-truss bridge, except that the truss can be a higher, deeper segmental curve

- Suitable for 50m - 150m spans

- Attractive

- Can be constructed on less robust foundations e.g. atop elevated piers/areas of uneven soil

- Can be pre-fabricated offsite and hauled or lifted into place

|

|

|

|

|

|

|

|

|

|

|

|

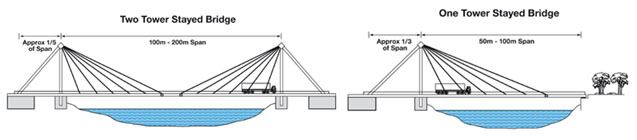

5. Steel Cable Stayed Bridge

Although expensive, stayed bridges may be the only viable alternative when: there is no access to the gap, on which temporary or permanent piers could be built; when there is no straight level run up to the gap which would permit cantilever launching; when the span is too big for regular through truss bridges. And, in particular, one-tower bridges are useful if there is no good access to the far bank, as they can be built from one side only. But please note: you still need enough space for the large counterweights, which may need to be one fifth of the span for a two tower bridge.

- Long span (50m - 200m)

- Very strong, but also flexible

- Economical as allow a slender and lighter structure which is still able to span large distances

- Light weight is an advantage in earthquake-prone areas

- Modern and simple design makes attractive and distinct landmarks

- Easy to build in segments where in-situ construction or cantilever launch on rollers is not possible. This requires substantial piers and large counterweights

- Less suitable for very windy places due to its lightness

|

|

|

|

|

|

|

|

|

|

|

|

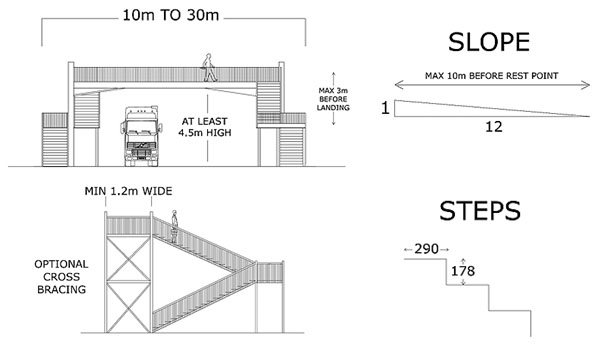

6. Steel Pedestrian Bridge

- Designed for pedestrians and cyclists rather than vehicular traffic

- Useful for crossing water/railways where there are no road bridges

- Allow safe crossing of busy roads

- Can also be used for walkways between buildings or in car parks

- Must be at least 1.2m wide (unless designed for maintenance work only), but can be as wide as needed

- Can be the simplest beam type with hand rails, or a through-truss with hand rails fixed to the two trusses

- Through-trusses useful if the bridge is to have overhead cover and sides with cladding or mesh (essential for road or rail crossings)

- Usually require stairways and ramps

|

|

|

|

|

|

|

|

|

|

|

|

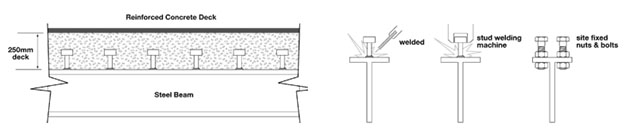

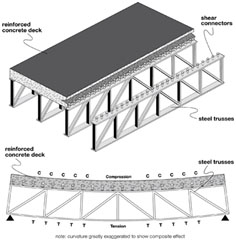

7. Composite Beam Bridges

Word 'Composite' means that the steel structure of a bridge is fixed to the concrete structure of the deck so that the steel and concrete act together, so reducing deflections and increasing strength. This is done using 'shear connectors' fixed to the steel beams and then embedded in the concrete. Shear connectors can be welded on, perhaps using a 'stud welder', or better still on export work, by fixing nuts and bolts. |

|

|

|

|

|

|

|

|

|

|

|

Shear connectors, correctly spaced to resist the loads, make the concrete work 'compositely' with the steel.

Usually the steel carries its own weight and that of the wet concrete. But when the concrete is 'cured' and has acquired its full strength, then all future loads (traffic, surfacing, wind, water, pressure, seismic loads) are shared by the steel/concrete composite.

The concrete is good in compression, while the steel is good in tension and compression. This composite bridge design can be used in the following ways: |

|

|

|

|

|

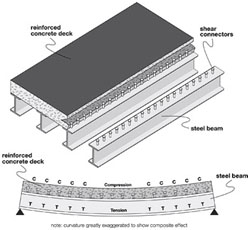

1. Simple Beam Bridges

On short spans (8m, 10m, 15m and then more expensively up to 24m), bridges can be made from a number of beams under the roadway straight across the gap. The bridges benefit the most from composite action.

Annotation: exaggerated deflected shape showing bending, with concrete carrying some of the compression (C) and steel carrying all the tension (T). |

|

|

|

|

|

|

|

2. Over Truss Bridges

These are similar to simple beam bridges but for longer spans, from say 18m up to approx 100m. The deck is still on top of the steel structure, so goes into compression when deflected.

Annotation: As with the simple beam bridges, the concrete can share the compression loads (C) with the steel trusses |

|

|

|

|

|

|

|

|

|

|

|

|

|

3. Transoms on any type of bridge

Transoms go from side to side across a bridge and carry the deck loads to strong steel frames on either side. This is usually on 'open top' through truss bridges or 'closed-top' through truss bridges.

Annotation: Again the transoms bend down under load and the concrete contributes to compression strength. |

|

|

|

|

|

|

|

Annotation: Again the transoms bend down under load and the concrete contributes to compression strength. |

|

|

|

|

|

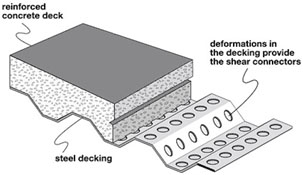

4. Decking

In a normal steel building the concrete can act together with steel decking, the steel decking taking the place of the regular steel reinforcing bars within the concrete. However in a bridge, the underside of the decking is liable to corrode over time, so is not counted as part of the reinforcement. It is just used as 'lost formwork'. |

|

|

|

|

|

|

|

|